PROQUA

THE PROJECT OF THE

BUSSINESS-SYSTEM FOR THE QUALITY ASSURANCE

The project has the object to requalify the firm with the purpose of full

client's sadisfaction. This required the realisation of an effective control

of the technical production-system. That's the reason why the porject

has been articulated in twoo different phases.

1. replaning and realisation of the planing and programmation of

the produktive resorces;

2. realisation of a specific intern quqality system;

The

first phase:

The clients are allways more oriented to order in small quanities. So

they eliminate accumulations of burdensome goods in the storehouse and

avoid qualitiy control of the entering goods. They have the objective

to put the goods directely on the production line.

Enunciated opened a innumerable quantity of organisation and practical problems. The end consumer doesn't see this problems, but we had to work for some month to find a practical sollution. This work can be described with one word: flexibility.

Stock

reduction

- improvement of the victualling palnification

- improvement of the manufacture planification

- new criterions for the production programmation based on client's orders

"aslo late one's"

Cost

reduction

- realisation and semplification of the following procedurs: registration

of the orders, the material's supply, the stock, the planning of the production,

the forwarding;

- the new programming of the organisation structure, new recomposing and

reassigning of the duties and competences;

Higher

client's service level

- reduction of the delivery times;

- mantaining the delivery dates;

- synchronising the elaboration and transformation procedures;

- better cooperation of the commercial office with the production;

- quality control;

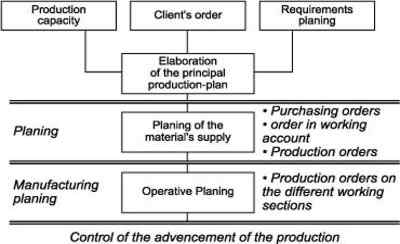

The following

graphic shows semplyfied, the planing and the programming of the manufacture-process:

il

processo di pianificazione e programmazione operativa della produzione

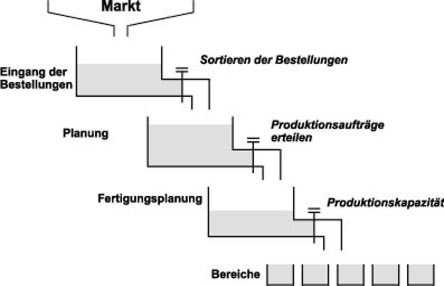

This was the creation of three different organisation and information moments, rappresented in three basins in the following graphic.

In the first basin are gathered the client's orders, some per quality, some per quantity, some per articles and other per delivery dates. The planing who is working on the basin underneath is organising the client's orders with the delivery forcast and predisposes eventual orders to our purveyors for the prime material. Weekly the orders are going to the production in the basin underneath.

The operative programming is organising a weekly production plan to execute, releasing every day at the different departments of the production the necessary informations for the manufacturing. The daily information of the proceeding of the works in production, makes the release of the next days manufacturing plan possible.

The returning

work-proceeding informations makes possible:

- opening and closing the taps we can change the levels of the orders

in the different basins;

- speak with our clients about the delivery dates;

The second phase:

In the

second part of this project the firm decided to improve their service

with a wide ranged quality control. For this reason today we are working

according to the norm UNI EN ISO 9002. The norm is concentrated

on the following activities:

- formation and professional training of our personal inherent the tecnical

aspects of the procedure of quality ensurance;

- the organisation of the quality control with the dimensionment of the

resources and the definition of the operative and productive modalities

in accordance with the norm UNI EN ISO 9002;

- writing out

the norm and procedures as documentation of the quality system (quality

handbook);

All the activities relative at the second phase of our project are strictly connected with the first phase. Especially the data base, the support implements and the realised operative procedures are predisposed for the successive quality control of the firm. All the business functions are directly involved in the changing process, with different measures. The projects are different inspite of the high intergration factors. But they have the same goal: the realisation of the quality control.

The changements we made in the following departements are the following:

a. the reorganisation of the commercial office, with changements in the procedures and the planing of the entered orders, has emproved our capacity to enform our client's about the exact delivery times and the advancement of the work.

b. in the production the planing has been changed, so we got an emprouvement to response at the marcet enquiry.

c. at the tecnical direction has been given the responsability for the projection of the production- cyclus. They have to controle the tecnical aspects and the one's who are relevant for the business- management.

d. the planing, which is not showed in the old organigramm, is searching and coordinating the marcet dynamik with all the operative possibilities of the firm.

e. the quality assurance is integrated in the businessorganigramm without any hierarchic system.

Predisposition of the quality-handbook

The object of the quality-handbook is to communicate at the inside (organisation structure) and at the outside (marcet, client's, purveyors, official institutes...) the principals and norms followed by our firm with the goal to assure the quality.

The contest of the quality-handbook of the G. Guerra Group spa has the followein subdivision in capitals:

- structure

of the quality handbook

- responsabilities of the management

- quality system n reexamination of the contracts

- control of the documentation

- control of the materials supply

- products delivered

from the commitent

- identification and tracing the products

- control of the manufacturing

- tests and controls

- control of the testing engines

- condition of the tests and controls

- methodic and conformity of the products

- corrections and prevention

- mouvementation, stocking, packing, conservation and delivery

- internal recontrolling and inspectations

- personal forming : norms and informations

- assistence

- tecnical statistics

The inspectation and the periodic monitoracion and the punctually actualisation of the procedures indicated in the quality handbook is valutating all the operative conditions, which are under the responsability of an function /service, of a firm department or of a purveyor.

The following persons in the organigramm are responsible for the indicated departement and the collaborators.